Vehicle technology analysis

Kiel University of Applied Sciences: Institute for Mechatronics, Prof. Dr.-Ing. Klaus Lebert, Prof. Dr.-Ing. Christoph Weber

Based on the real data from the operation of the hybrid trolley trucks, models are created that enable the technology comparison between OH trucks, battery electric powered trucks and classic diesel vehicles. These models can be used to map possible future scenarios and develop the comparison to alternative transportation concepts or the forecast for a larger fleet.

Vehicle components

In the eHighway Schleswig-Holstein field trial, so-called OH trucks (overhead hybrid trucks) are used. In addition to the classic combustion engine, the industry-built vehicles also have an electric motor. The vehicle can be driven conventionally, purely electrically or in hybrid mode. While the combustion engine draws its energy from the diesel fuel, the electrical energy for the e-machine is provided by the pantograph from the overhead line or by corresponding traction batteries. The battery can be recharged via charging stations, energy from the overhead line and recuperation processes (recovery of braking energy).

Preliminary investigations

In the run-up to the study, an evaluation method was developed on the basis of real data from an electric vehicle in order to automatically detect driving maneuvers and evaluate them. In the current operating phase, this methodology will be applied to the real data basis and the behavior of the OH truck will be further analyzed. For this purpose, data on speed or acceleration and braking processes are examined, among other things.

Driving data acquisition and processing

Telematics data recorded by the industry from the daily operation of the OH trucks will be made available to the accompanying research via a separate project. These are data of varying quality transmitted in 10-minute segments. For later evaluation of the data and for the purpose of model validation and adaptation, the real data are analyzed and filtered via specially written programs to obtain relevant and coherent driving data with and without overhead contact line contact. This necessary preliminary work makes it possible to subsequently perform an analysis of the reliability of the overhead contact line system in interaction with the pantograph, the energy consumption or forCO2 balancing.

Technology comparison

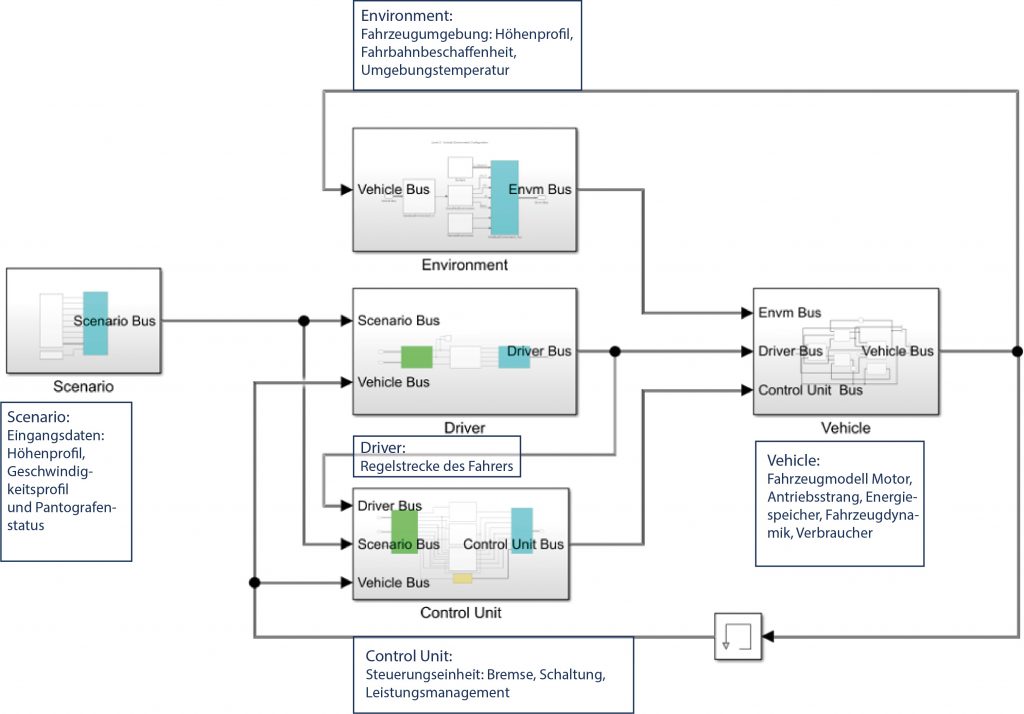

Based on the real data, models will be built to enable model configurations for direct technology comparison between OH trucks, battery electric trucks and diesel trucks, as well as an analysis of energy efficiency. The model should reproduce the behavior of the real vehicle sufficiently accurately. It follows the specified speed and replicates the vehicle’s electricity and diesel fuel consumption, among other things.

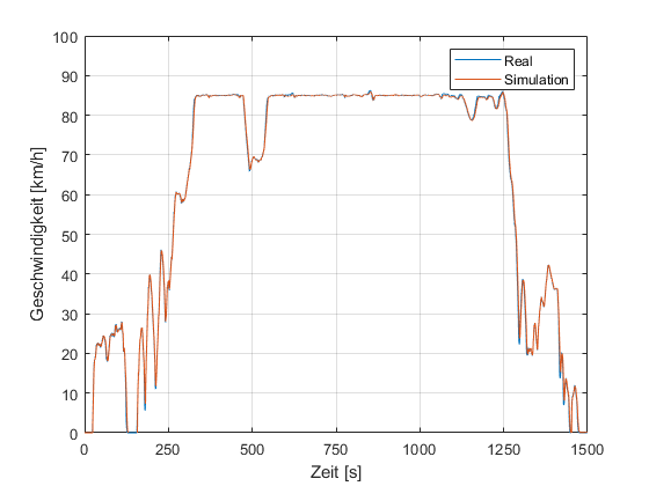

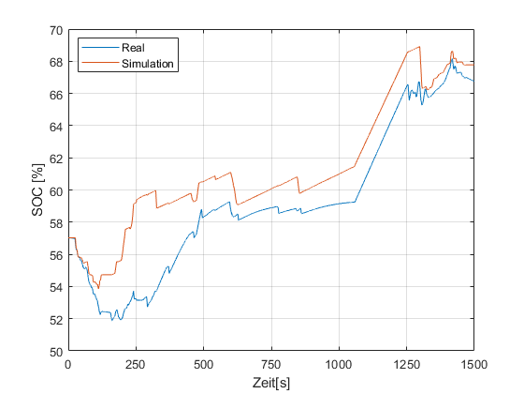

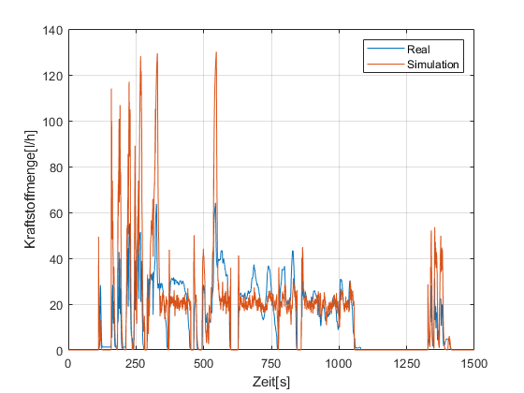

Validation of vehicle speed and consumptions

The simulation data will be compared with real data from the eHighway field trial to validate the model. In the figure below, it can be seen that the vehicle follows the given speed from the real data. A convergence between real vehicle and simulation data is also evident in consumption and battery state of charge (SOC) (see figure for model validation of diesel fuel consumption and model validation of battery state of charge).

The models can be used to simulate different scenarios that would be difficult or costly to reproduce in reality. In addition, the model can be used for a comparison to a purely battery-powered concept (without overhead line system) as well as a forecast on larger fleets. Necessary infrastructure measures (charging stations, etc.) are also taken into account.

Energy efficiency

For an efficiency analysis and in order to be able to draw a technical comparison of the vehicles, performance balances are drawn up between a conventional diesel truck and an OH truck, among other things. Potential savings inCO2 emissions can thus be identified. The analyses will relate to individual driving maneuvers such as accelerating, overtaking, braking, constant speeds. Thus, they could further be used as a basis for new driver information systems.

Prof. Dr.-Ing. Klaus Lebert im Interview

Prof. Dr.-Ing. Klaus Lebert von der Fachhochschule Kiel arbeitet in dem Feldversuch eHighway Schleswig-Holstein primär an der Analyse der Fahrzeugtechnologie und erzählt im Interview mehr zu den Methoden und ersten Erkenntnissen auf seinem Feld.

Eine Methode ist die sogenannte digitale Modellierung. „Jetzt können wir natürlich nicht die gesamte Infrastruktur z.B. in die Kasseler Berge bringen, auf die A7. Aber was wir können, ist mit dem Abgleich eines Simulationsmodells […] einen diesem Testversuch entsprechenden Lkw virtuell auf eine neue Strecke bringen.“, erläutert Professor Lebert.